Cement

We have 30 plants and 20 cement grinding mills worldwide, and we are qualified to supply the most varied specifications of cement for constructions of all sizes. With an installed production capacity of million metric tons per year

WhatsApp)

WhatsApp)

We have 30 plants and 20 cement grinding mills worldwide, and we are qualified to supply the most varied specifications of cement for constructions of all sizes. With an installed production capacity of million metric tons per year

Mill Grinding Course. PCA offers an opportunity to learn the latest technical training on raw grinding and finish milling circuits and evaluation of their efficiencies over this twoday course.

Dec 11, 2016· Cement MillsThe grinding of cement clinker and granulated blast furnace slag in roller Thanks to the high production rates of Vertical cement grinding mill supplier,Cement production line Cement ...

important to optimise the existing mill installations as far as the grinding process is concerned and also to use high quality spare parts and consumables like grinding media . Ball mills are predominantly used machines for grinding in the cement industry. Although ball mills

Effect of grinding aids on closed circuit cement grinding As introduced before, grinding aids are sprayed in the mill, or added on the clinker, with dosages usually ranging from 100200 g up to 23 kg per ton of cement. Once a grinding aid is added during cement manufacturing, the main effect is the reduction of separator reject: more

Grinding Mill Used For Ore Slag Processing SHANGHAI SHIBANG MACHINERY CO., LTD is one hightech enterprise, which involves RD, production, sales and service as well. In the past 20 years, we devote to producing mining equipments, sand making machines and industrial grinding mills, offering expressway, rail way and water conservancy projects ...

Rock phosphate, iron ore application 1000 tpd cement clinker grinding plant for Philippines application: 1000 tpd cement clinker grinding plant is suitable in grinding limestone,ceromic,coking coaland so is mainly applied to the power processing of mineral products in the industries of mining,metallurgy,constrution materials and chemicl materials ect more than 280 kinds of high finesse ...

For the dry grinding of mineral and ceramic raw materials the agitator bead mill NETZSCH SpheRho ® impresses with very high product fineness and high throughput rates with low specific energy consumption.. For decades, agitator bead mills from NETZSCH have been successfully employed in a broad range of industries for the grinding and dispersing of suspended solids.

vertical mills cement grinding . Cement mills and raw mills for high throughput rat MVR vertical roller mill with MultiDrive, The highest wear occurs on the wear parts of the grinding elements as is the case with any type of vertical mill Therefore, ease of replacement and regeneration is a major feature of the mill, MVR 6000 C6 cement mill with MultiDrive®, Cement .

of the most energy consuming processes in cement production (60 70% of the total electricity consumed in a cement plant). Grinding aids are normally liquid products, traditionally formulated as waterbased solutions of organic compounds with high charge density, such as glycols, esters of glycols, alkanolamines and/or

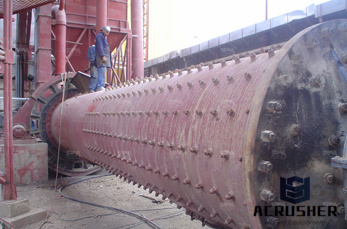

Cement Ball Mill. Cement Ball Mill is an efficient tool for fine powder plays important role in cement production plant. Cement Ball mill is widely used in building material, chemical industry, Ball Mill is used to grind many kinds of mine and other materials, or to select the mine.

Lvssn provides various grinding equipment for cement production line, including: Grinding mill,Ball mill,Rod mill,Roller press,Veritcal mill,Pipe mill

The ConJet ® highdensity bed jet mill is a spiral jet mill combined with a patented dynamic air classifier. This classifier enables the ConJet ® to achieve highest finenesses independent of the product load, and therefore also highest throughput rates. Applicable for finenesses from to 70 µm (d97). Machine sizes available for grinding air volumes from approx. 50 to 2,400 Nm³/h.

Cement Mill has been used in many industries for a long time, the technology is quite mature already. But there is still some problems, such as, lots of investors expressed that the metal balls are easy to be worn out and the energy consumption is quite high.

A cement mill is key equipment for recrushing the materials after they are primarily crushed. It is widely used in the dry type and wet type powder grinding of all kinds of ores and other grindable materials in cement, silicate product, new type building material, refractory, fertilizer, ferrous metal, and nonferrous metal beneficiation and glass and ceramic production industry.

Manufacturer of High Chrome Castings Cement Mill Liners And Diaphragms, Cement Mill Liners, Mill Liners and Haze Mags Blow Bar offered by Shilpa Alloys Private Limited, Jaipur, Rajasthan.

Vertical Grinding Mill MTW Series Trapezoid Grinding Mill Micro Powder Grinding Mill Trapezium Grinding Mill High Pressure Grinding Mill T130X Enhanced Superfine Grinding Mill European Hammer Mill Raymond Mill Ball ... White Cement Production Line. Currently, Market of White Cement Production Line in China''s competition is so fierce. (Want ...

cement clinker grinding plant has overcome the traditional mill''s defect completely in application, capacity, fineness, energy consumption, service life, etc. And it is the ideal substitute of the traditional mill, such as Raymond mill, high pressure suspension mill, ball mill, etc. Low price China cement clinker grinding plant application:

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Most importantly, the mills are customisable to each unique mining application, optimizing the performance of the mill and recovering more ore for your business. Our stirred mill and tower mill solutions offer a range of advantages, designed to optimise your milling while solving a number of issues traditionally related to industrial grinding:

Dec 01, 2017· Grinding cement requires a great deal of energy. As the fineness of the cement increases, it needs more energy to grind it. But every cement quality band has a certain fineness requirement. In one example mill, we consider the fineness and the energy consumed for eleven months for a cement mill.

General approach for production of PLC is to grind the cement to a higher Blaine fineness to try to match the early strength of OPC longer grinding time = lower mill production longer grinding time = higher energy requirement focus on earlyage strength can reduce lateage strength Formulation target: efficient grinding aid

According to the display of pulverized coal measured data, the vertical mill can be saving electricity above 30% use of vertical roller mill production per ton cement clinker than traditional tube mill, and the power saving effect is very remarkable. 3. Stable, highefficiency and environmental protection

Increasing efficiency in cement production using precast refractory solutions Harpreet Singh, Hasle Refractories A/S (Denmark) ... Utilisation of AFs from various waste streams in the production process of high quality clinker Stelios Sycopetrides Dr Iacovos Skourides, Vassiliko Cement (Cyprus) ... Vertical roller mills for cement grinding.

WhatsApp)

WhatsApp)