vertical roller mill working principle YouTube

May 12, 2017· vertical roller mill working principle TOOWELL CHINA. Loading... Unsubscribe from TOOWELL CHINA? ... loesche Vertical Mill LM Duration: 12:11. modo1231 84,133 views.

WhatsApp)

WhatsApp)

May 12, 2017· vertical roller mill working principle TOOWELL CHINA. Loading... Unsubscribe from TOOWELL CHINA? ... loesche Vertical Mill LM Duration: 12:11. modo1231 84,133 views.

LM Vertical Mill LM series vertical mill is an efficient equipment which combines crushing,drying, milling, separating and transporting together. It is wildly used in field of cement, metallurgy, electricity, chemical,ceramics, glass, nonmetal ores,etc.

LM Vertical Grinding Mills Working Principle. The main motor drives the disc through the speed reducer to rotate, and the hot air from the air inlet into the vertical grinding mill body, material from the feeding port to the central disc and under the action of centrifugal force from the disc center to the edge of uniform movement, after roller ...

crusher mill products grinding mills pendulum grinder mill; ... manganese mm ball for ball mill; vertical shaft impact crusher sand making price in india; mobile crusher br200j; used horizontal ball mill for sale; ... LM Vertical MiLL; About Us.

LM Vertical Grinding Mill. LM series vertical milling machine is largescale grinding equipment, which is developed and launched by Zenith, sets medium crushing, drying, grinding, classifying and other functions as a whole, being the ideal equipment in the grinding industry. Working Principle of LM Vertical Grinding Mill

vertical mill operating principle vertical mill operating principle vertical mill operating principle Principle and Working of MILLING MACHINE Engineering Tutorials. Oct 21, 2009 . Introduction: Milling is the cutting operation that removes metal by feeding the work against a rotating, cutter having single or multiple cutting.

the principle of vertical raw mill operation. Sep 04, 2018· the principle of vertical raw mill operation. % 108000 M TOP 1% 151 3500 IntechOpen ... namely LM vertical mill and LUM ultrafine vertical There are many different forms of vertical mill, but the working principle is Roller Mill For Chinese Medicine Industry ; Vertical Roller Mill .

Working Principle of Pellet Mill and Pellet Plant. EQUIPMENT USED WITHIN A PELLET PLANT The Pelletizing System The pelletizing system is composed of several different machines, such as pellet mill, hammer mill, mixer and cooler, designed to most efficiently accomplish the pelletizing typical system arrangement with equipment names is shown in Kingman product list.

ginding mill,Working principle of grinding mill,grinding mill use scope. Working principle of vertical grinding mill. The motor drives the disc through the speed reducer to rotate, small Raymond mill also hot air can enter from the air...

Working Principle Of LUM Series Ultrafine Vertical Roller Mill. Motor through reducer drive disc rotates, the material through the air lock feeder from the inlet falls central disc, while the hot air from the inlet into the mill.

Oct 21, 2009· Flat or curved surfaces of many shapes can be machined by milling with good finish and accuracy. A milling machine may also be used for drilling, slotting, making a circular profile and gear cutting by having suitable attachments. Working Principle: The workpiece is holding on the worktable of the machine. The table movement controls the feed ...

Vertical Roller Mill maintenance measures. The rainy season is a feature of summer. The technicians of the Vertical Roller Mill will experience how to maintain the summer Vertical Roller Mill during the summer lightning flashing in these areas, the hot summer weather and the humid summer weather.

LUM Ultrafine Vertical Roller Mill is widely used in grinding nonflammable and nonexplosive materials under (the Moh''s hardness), such as grinding quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

The cutter revolves at a fairly high speed and the work fed leisurely past the cutter as shown in figure. The work can be fed in a vertical, longitudinal or cross direction. As the work advances, the cutterteeth do away with the metal from the work surface to produce the desired shape. [21] : Working Principle of milling operation [21]

May 26, 2016· Today we will learn about milling machine operation. We have discussed about main parts and types of milling machine is my last post and know that milling is a most versatile machine used in mechanical industries. It can perform turning, facing, slot cutting, chamfering etc. to convert the work piece into desire shape.

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavyduty gang milling operations.

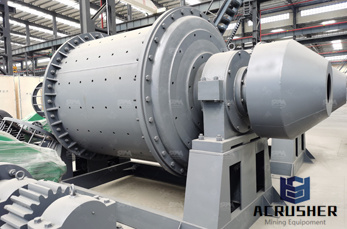

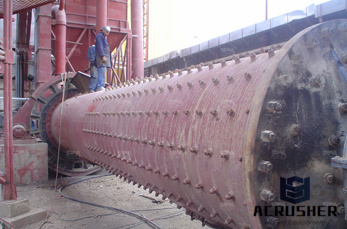

Jan 14, 2013· Ball mill working principle, How Ball Mill work?What is ball mill .. Ball Mill working Principle, How Ball Mill work?What is ball mill Application for? . LM Vertical Trapezium Coarse Powder »More detailed

Milling machine is the main machining operations. In this process workpiece is fed beside a turning cylindrical tool. Turning tool has of several cutting edges. Milling process is notable as of other machining operations on the foundation of direction between the tool axis with the feed direction, though, in other operations similar to drilling, turning, and so on.

May 12, 2017· vertical roller mill working principle TOOWELL CHINA. Loading... Unsubscribe from TOOWELL CHINA? ... loesche Vertical Mill LM .

Jul 13, 2017· This article, we are going to discuss what is Milling Machine? and How does a Milling Machine works? We also Highlighted the Working Principle, Parts of the Milling Machine, Types and kinds of Milling Machine. Milling is the cutting operation that removes metal by feeding the work against a rotating, cutter having single or multiple cutting edges.

The Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications (LM D to LM D), with table diameters from 1,200 to 2,000 mm. Larger mills with two, three and four rollers and modular structures (LM D to LM D), with table diameters from 2,100 to 4,300 mm.

A milling machine is basically used for shaping, routing, boring, and drilling metals and other solid materials. Generally there are two categories of the milling machine which include the vertical type and the horizontal type. In order to optimize the capacity of the milling machine, it is essential to identify the appropriate milling machine type for specific tasks.

Working Principle. The motor drives the grinding disc to rotate through decelerator. The material falls on the center of the disc from the feeding opening, at the same time the hot air enter the mill from the air inlet. ... LM Vertical Roller Mill Project Case: The Rubber Lining Of Ball Mill. Trapezium Mill Structure And Parts. High Efficiency ...

Wind turbines operate on a simple principle. The energy in the wind turns two or three propellerlike blades around a rotor. The rotor is connected to the main shaft, which spins a generator to create electricity. Click on the image to see an anim...

WhatsApp)

WhatsApp)