Silica Silica Sand Supplier Industrial Minerals ...

Silica is a leading silica sand supplier with a focus on performance materials that are essential to modern living. Our stateoftheart offerings are used in variety of Industries and Applications.

WhatsApp)

WhatsApp)

Silica is a leading silica sand supplier with a focus on performance materials that are essential to modern living. Our stateoftheart offerings are used in variety of Industries and Applications.

The main purpose of silica sand is the product expansion to make glass, casting, ceramics and refractory materials, smelting and other relevant. However, processing, processing for silica sand, according to different purposes appeared many for silica sand mining equipment, which is widely is silica sand crushing machine, milling machine and so on.

Screening equipment used at the facility in Wedron, IL, faces harsh conditions 24 hours a day, seven days a week. Rotex Inc., Cincinnati, a global leader in screening technologies, knew that Wedron Silica would put its new APEX dry separation screener to the test. Each day, the screener needed to process more than 150 tons of sand at the Wedron ...

Cone Crushers I Hammermill Crushers I Impact Crushers Primary I Impact Crushers Secondary I Jaw Crushers . Screening/Sizing. McLanan offers both stationary and portable screening and sizing equipment effective for making the coarseend separation required for frac sand, as well as scalping off the unwanted fractions.

Home / Foundry and Metalcasting Solutions / Sand Systems / Reclamation / Sand Conveying and Screening Equipment Sand Conveying and Screening Equipment. ... Rotary Sand Screen. General Kinematics DUCTASCREEN™ Rotary Sand Screen blends and conditions sand, all while removing tramp metal and core butts for a cleaner sand recycle back to your

JXSC Mining Equipment for sale! Complete mineral processing equipment, rock crusher, gold wash plant, magnetic separator, magnetic separators, flotation machine, etc.

This highcapacity wet screening and dewatering unit is designed to dewater up to 300 TPH (Tons Per Hour) of primary sand products, delivering highquality production sands (asphalt, concrete, mason, and others). Each unit houses over 62 square feet of screen surface area, of which nearly half is open area, resulting in an efficient and highvolume dewatering capacity.

As the demand for quartz sand has become greater, silica sand mining is very popular with investors. But how to choose the silica sand mining equipment, reduce operating costs in sand making projects and maximize profit, which will be the problem that everybody cares ''ll discuss this .

Silica Sand is AGSCO''s most popular product and it is offered in every size, shape, and color possible. Let us know about your specific application and we will help guide you into the right sand for your needs.

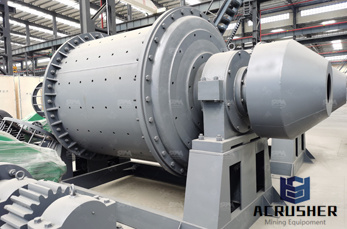

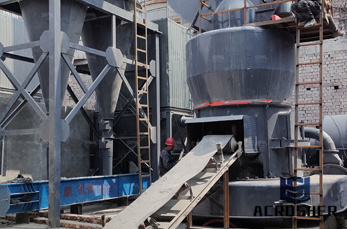

Silica Sand Production Equipment. Silica sand is actually what we call quartz sand. It is mainly obtained by crushing, screening, washing and drying of natural silica (quartz) raw materials.

Silica Sand Screening Operation. Silica sand screening is a mechanical operation which separates particles according to the particle sizes and their acceptance or rejection by openings of a screening face. Silica sand particles that are bigger than the apertures .

Bulk Processing Equipment. Preprocessed, sand and gravel have an array of applications like fill, bedding, subbase and base course; and that''s just their uses during the preprocessed state. However, most sand and gravel is processed before being utilized domestically.

Silica sand washing plant includes Jaw crushers, wet rod mill, hydraulic classifier, desliming machine, magnetic separator, silica sand concentrate dewatering screen, tailings dewatering.

Sinonine can provide you with very effective help in the field of quartz/silica sand washing plant. Sinonine is proficient with key technology in sand washing, quartz/silica sand purifying, sand making. Sinonine has developed efficient sand washing machine, quartz/silica sand production equipment, quartz/silica sand purification equipment.

The Equipment Of Silica Sand Washing Plant. Silica sand washing plant consists of vibrating feeder, jaw crusher, VSI crusher (silica sand making machine), vibrating screen, silica sand washing machine, belt conveyor and centrally electric controlling system, .

Corporation has been serving the needs of the silica, frac and industrial sand industries for over 50 years. ''s robust dry and wet screening machines and high open area Polyweb ® urethane screen panels have a proven track record of continuous, low maintenance operation in challenging, abrasive applications. The commitment to Pioneering Technology for the sand industry ...

What''s New in the OSHA Silica Standard? Previously the Permissible Exposure Level (PEL) for respirable silica was 100 µg/m 3 for an 8hour time weighted average (TWA). The new OSHA Silica standard establishes an 8hr TWA PEL of 50 µg/m 3, half the old PEL, so it''s no wonder contractors are concerned and calling for silica air addition to testing requirements, "all ...

offers 1,277 silica sand screening machine products. About 44% of these are vibrating screen, 1% are mineral separator, and 1% are other farm machines. A wide variety of silica sand screening machine options are available to you, such as circular, linear.

offers 1,277 silica sand screening machine products. About 44% of these are vibrating screen, 1% are mineral separator, and 1% are other farm machines. A wide variety of silica sand screening machine options are available to you, such as circular, linear.

Screening machines, screening equipment and vibrating screen for fractioning and bulk material handling

Silica Sand Screening Equipment What are the Health Effects? Screening Treatment. To make sure your doctor is aware that you may have been exposed to silica on the job, and is well informed on the signs, symptoms, and diagnosis of silica related illness, we recommend bringing a Physician''s Alert (English and Spanish) to your medical examinations should include:

Output of sand screening machines is depends on the sieve mesh size we are using and the dryness of the sand. If we use big size sieve mesh in this sand screening machine, we will get more output. Similarly if we use dry sand instead of wet sand the out from this Sampath''s Sand Screening .

offers 2,167 silica sand screen machine products. About 1% of these are other packaging machines, 1% are other food processing machinery, and 1% are other machinery industry equipment. A wide variety of silica sand screen machine options .

When we say Industrial Silica Sand it generally means high purity silica sand as raw material with closely controlled sizing. We as a leading sieving, screening filtering solution provider in market, serve the best screening equipment''s that can help in screening sieving of Silica sand with fine quality precise desired size.

WhatsApp)

WhatsApp)