Small scale gold processing plant YouTube

Aug 11, 2015· Small scale gold processing plant Chemist Sibanda ... Ancient gold smelting rare today. extract recovery process of refining gold to remove any ... Summer 2013 hard rock mill setup. Gold .

WhatsApp)

WhatsApp)

Aug 11, 2015· Small scale gold processing plant Chemist Sibanda ... Ancient gold smelting rare today. extract recovery process of refining gold to remove any ... Summer 2013 hard rock mill setup. Gold .

In the table, below, is a basic sampling equation that relates particle size to the amount of sample to be taken, with constants derrived for varions types of ore bodies. The values for "M" are the sample size required in pounds. Tha values of k are the constant derrived for differing ore bodies, in this example gold.

Oct 08, 2015· This video is part of a Gold Mining and Mineral Prospecting course. In this video I explain how I would sample a gravel bar to find a pay streak of gold.

Metallurgical ContentConcentrator Slurry SamplingMineral Processing Sampling MethodsHand Sampling of PulpMechanical SamplingThe Flowsheet and the Circuit'' Sample Points Concentrator Slurry Sampling In milling operations sampling is essential to proper control. This can only be based on the results obtained through sampling the various materials throughout a plant.

Ore processing is a 24 hour operation. Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added (2) to raise the pH of the ore.

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration. The flowsheet is ideal for a pilotplant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a larger plant or for processing ore ...

Oct 26, 2011· Vetran miner Mike Reynolds takes us through a tour of a gold processing mill that he has been working on for several years. He explains the process of taking the raw material and extracting the ...

process, enabling you to have the right sampling equipment integrated into the right places in the mill. In the latter option, the program is then supported by effective testing and reconciling procedures right from startup. In either case, our met accounting experts start the process with a systematic metallurgical plant audit. The plant audit

Ore Processing Mill. The mineral processing operation at Jerritt Canyon is one of only three processing plants in Nevada that uses roasting in its treatment of refractory ores. Initially, Jerritt Canyon was designed to process oxide and mildly refractory gold ores.

Be the first to see new Process Plant Manager Gold jobs. My email: By creating a job alert or receiving recommended jobs, you agree to our Terms. You can change your consent settings at any time by unsubscribing or as detailed in our terms. Indeed helps people get jobs: Over 10 million stories shared.

The remainder of the material passing through the rollscreen is weighed out in 10 kg. lots, and fed with the coarse ore into the stampmill. The sampling and assaying of a Nova Scotia goldore by the above method is entirely inaccurate, and the only justification for the procedure is that the results when compared with the true goldcontent of ...

Aug 07, 2016· The gold inventory, that is the gold present in the plant at any instant in time, will vary due to factors such as feed grade, equipment availability, feed rate etc. Inventory sampling is ...

The process design of gold leaching and carboninpulp circuits 14 JANUARY/FEBRUARY 1999 The Journal of The South African Institute of Mining and Metallurgy Figure 2—The CarbonInPulp (CIP) process Figure 1—ComputerAided Process Engineering (Cape)

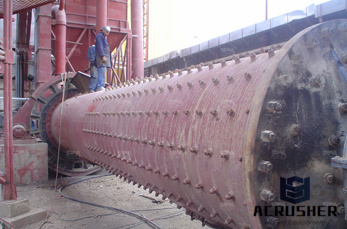

A standard ball mill may grind your ore to 75 microns. Fine grinding is one process available to liberate refractory gold. Gravity Recoverable Gold (GRG) refers to how much gold you can recover based on how fine you are grinding/milling your ore. The GRG (Gravity Recovery Gold) .

Jan 04, 2018· Rock gold ore process plant in Zimbabwe Africa Duration: 2:56. Rocky Chen 13,864 views. 2:56. Very rich gold ore crushed and processed. Nice surprise! ... Gold Processing Mill .

If the cutoff grade is one gram per tonne (/t) all rock with more than /t of gold will be marked out as ore while all rock which contains less than /t of gold will be marked out as waste rock.

Sampling of runofmine mill feed— A practical approach by Afewu and * Synopsis A modified approach to the implementation of Gy''s sampling theory is discussed and used to design a procedure for sampling crushed gold ore feed to metallurgical process plants. The approach involves calibration of certain orespecific parameters ...

The status of sampling practices in the Gold Mining Industry in Africa was determined as an initial step in a process to standardise sampling practices in the Mining Industry. Several mines, metallurgical plants and laboratories were visited and the status of equipment, standards and procedures were rated to .

Retreatment of Residues and Waste Rock Bosch Introduction From the commencement of gold mining on the Witwatersrand in 1887 up to 1984, a total of approximately 4,2 billion tons of gold ore has been milled in South Africa. The deposition of gold mine residues has left the country,

This chapter discusses process simulation in the gold industry. The many advantages of constructing a computer simulation model of a operating gold plant are described. Different areas of a gold plant require different types of simulation model, and these are discussed, together with some insights into the differences in the relevant software.

SAMPLE SIZE AND MEANINGFUL GOLD ANALYSIS By II. EDWARD CIJIF''l''ON, RALPH E. HuNTER, FREDERICK J. SwANSON, and R. LAWRENCE PHILLIPS ABSTRACT A sample of geologic material is of adequate size for gold nnalysis if it is large enough to insure tbllit the analysis will have n specified degree of precisio·n. It can be shown

Reconciliation involves the collection of tonnage, grade (quality) and contained metal (product) data from disparate and hopefully independent sources. Examples are exploration data, production sampling data from blast holes or draw points, and process plant data. These data may be compared by means ...

The AVR process, with various specific modifications, has now been installed in several gold cyanidation plants throughout the world. The process has also been successful in the application to silver cyanide leaching circuits for the recovery of cyanide for reuse (Botz and Mudder, 1998). Thus in the Kinross DeLamar Mining Company in the USA ...

Throughout the extraction process at the Waihi Gold mill, samples of solution, solids and activated carbon are removed for analysis to determine the efficiency of the process. The solids and the carbon samples are analysed by the fire assay technique for gold and aqua regia for silver.

WhatsApp)

WhatsApp)