separation process for titanum oxid from iron ore

Jan 25, 2016 ... iron sand and titanium separation process Keywords: Beach sand Sri Lanka ... Magnetite Ore Crusher,Magnetite Ore Processing,Mining Equipment. ... (Iron Titanium Oxide), .

WhatsApp)

WhatsApp)

Jan 25, 2016 ... iron sand and titanium separation process Keywords: Beach sand Sri Lanka ... Magnetite Ore Crusher,Magnetite Ore Processing,Mining Equipment. ... (Iron Titanium Oxide), .

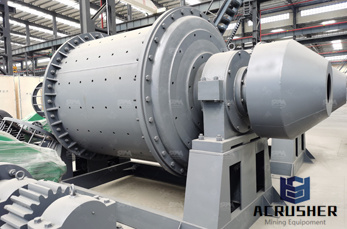

Iron Mining Process . At the processing plant the taconite is crushed into very small pieces by rock crushing machines The crushers keep crushing the rock until it is the size of a marble The rock is mixed with water and ground in rotating mills until it is as fine as powder Separation The iron ore is Ore processing .

Tin ore separation process The density of tin ore is bigger than paragenetic mineral, so we use gravity concentration to processing tin ore . Because there are many oxide iron ore inside, for example : .

Jun 20, 2016· Pilbara Iron Ore Processing Plant. 25Mtpa iron ore plant complete with crushing, screening, fines lump stacking and reclaim systems, and train loadout facilities. Worlds best iron ore processing ...

Iron Ore Processing Plant Xinhai. iron ore slurry is pumped to the agitation tank. This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore (~ mm) going to froth flotation cells for recovery of iron. magnetite processing plant,the process of flotation separation is replaced by magnetic ...

Magnetic separation of the roasted ore resulted in significant enrichment of the ore with respect to iron. The optimized parameters for reduction roasting were 13 mm particle size, 60 min roasting ...

Iron Mining Process Minnesota Iron. At the processing plant, the taconite is crushed into very small pieces by rock crushing machines. The crushers keep crushing the rock until it is the size of a marble. The rock is mixed with water and ground in rotating mills until it is as fine as powder. Separation The iron ore is . The Six Main Steps of ...

With teams located in major mining regions worldwide, we can work with you to supply Iron Ore beneficiation solutions across all stages of the project lifecycle. To find out more about how we can drive down operational costs and extract maximum value from your mineral processing .

The company that wants to build an ironore processing plant in northern New Brunswick is exploring whether it can get a break from the ... Eagle | Lundin Mining Corporation, The Humboldt mill is a former iron ore processing plant site that has been converted and refurbished to process Eagle mine ore.

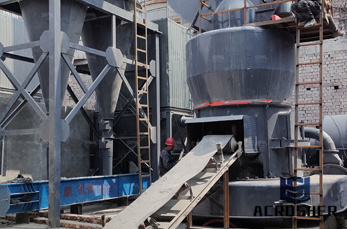

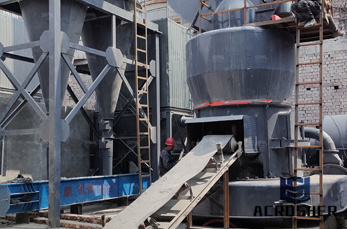

Iron Ore Processing Plant Xinhai. Iron Ore Mining Process Process Introduction There are a lot of iron ore in nature, which containes highly quantities of hematite or mainly iron ore beneficiation method is magnetic separation and flotation separation,so the mainly used iron ore .

with leading iron ore separation technologies. 5 countries 40 solid/liquid separation specialists 2,000 Your separation ... In designing a new beneficiation plant or extension and modernization, our engineers draw on decades of ... Maybe it''s processing huge volumes of lowgrade ore with minimal residual moisture. Or doubling your

Mining Processing Iron Ore Vulcan® Systems. magnetic separation. Uses of Iron Ore. • 98 percent of mined iron ore is used to manufacture steel ... Small amounts of iron ore are also used in coal .

Apr 03, 2014· DSO, gravity separation, Iron ore, iron ore beneficiation, magnetic separation, Beneficiation of Iron Ores. Iron ore is a mineral which is used after extraction and processing for the production of iron and steel. The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron. magnetite).

High Efficiency Automatic Vertical Shaft Adjustable Hammer . iron ore separation of gold using cyanide processing cheap gold mineral mining in niger iran gold mineral processing pilot project products goldic separator gabbro sharpgold ore vibrating grinding ball mill with cali ball mill ore dressing ore lead ore processing .

iron ore slurry is pumped to the agitation tank. This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore (~ mm) going to froth flotation cells for recovery of iron. magnetite processing plant,the process of flotation separation is replaced by magnetic separation.

Magnetic separation is commonly used for magnetite. Gravity separation is commonly used for hematite. Flotation is mainly used to process limonite and other kinds of iron ores. Through detailed mineralogy study and lab processing test, a most suitable processing plant .

The gravity separation separates ore parts with different density. Gravity separation is also one of the most popular ore beneficiation methods. It is widely used in weight metal ore beneficiation, especially weak magnetic iron ore. Magnetizationmagnetic separation process and equipments

Iron Mining Process Minnesota Iron. At the processing plant, the taconite is crushed into very small pieces by rock crushing machines. The crushers keep crushing the rock until it is the size of a marble. The rock is mixed with water and ground in rotating mills until it is as fine as powder. Separation The iron ore .

hot selling iron ore flotation machine plant. Malaysia tin ore processing machine, 200 tph crusher plant, iron ore production line magnetic separation process line with ISO and CE certificates hot selling Airinfaltion Mining Flotation Machine Iron ore 68%,flotation machine price in Chat Onlineget price

Magnetic separation is commonly used for magnetite. Gravity separation is commonly used for hematite. Flotation is mainly used to process limonite and other kinds of iron ores. Through detailed mineralogy study and lab processing test, a most suitable processing plant .

We have Iron Ore Jigging Separation Processing Plant,Gravity ore dressing gravity beneficiation gravity separation is one of the main ore beneficiation methods, includes heavy medium separation dms hms, jigging, shaker concentrator, spiral chute concentrator. hms and mineral jigs suit for the coarse ore particle, shaker has a high dressing accuracy, can be used in the weak magnetic iron ...

Jul 16, 2020· Pilot plant will have the capacity to concentrate 30 tonnes per hour of dry ore, using magnetic separation technology, made by means of rare earth magnets.

Vale recently inaugurated, in Minas Gerais state, a pilot plant for magnetic concentration of lowgrade ore without using water. The Brazilian technology, known as FDMS (Fines Dry Magnetic Separation), is unique and has been developed by New Steel a company acquired in late 2018. The pilot plant, which cost US3 million, is the first step towards the construction of an industrial plant .

with leading iron ore separation technologies. 5 countries 40 solid/liquid separation specialists 2,000 Your separation ... In designing a new beneficiation plant or extension and modernization, our engineers draw on decades of ... Maybe it''s processing huge volumes of lowgrade ore .

WhatsApp)

WhatsApp)