Steel Rolling Mills Home | Facebook

Steel Rolling Mills. 4,977 likes · 9 talking about this. The Company with the name NATESA ENGINEERS is a leading Designer and supplier of Complete...

WhatsApp)

WhatsApp)

Steel Rolling Mills. 4,977 likes · 9 talking about this. The Company with the name NATESA ENGINEERS is a leading Designer and supplier of Complete...

American Steel Products Leading the Industry in a Variety of Rolling Mill Lines ASP Provides Hot Cold Rolling Mills for Businesses WorldWide. For over 60 years, ASP''s rolling mills provided the industry with high production 2high, 4high and cluster mills.

Mill Rolls. Kennametal manufactures mill rolls from cemented tungsten carbide grades tailored for the demanding environment of hot rolling mills that produce wire rod and seamless tube. We deliver mill rolls as unfinished blanks, semifinished rolls with ground inner diameter and thickness, or rolls fully finished to your drawing.

Section Rolling Mill. Rolling mills are facilities that carry out a series of processes including rolling the billets, blooms, slab and beam blanks – extracted from the reheating furnace – into the prescribed size and correcting any bending, cutting them into given lengths, then piling or bundling as needed for shipment.

Let''s see how the operation of hot rolling mills works. Knowing the process will allow you to find the right rolling mill rolls manufacturer easily. Steel rolling is the process of reducing the crosssection of large ingots or plates in bulk. The main focus is to produce finished or semifinished components that have various applications.

talking about the steel rolling mill roll Operation of Rolling Mills Schweitzer Rolling . Operation of Rolling Mills Rolls Rolls are the tools of the rolling trade and the way they are used to execute their duty of deforming steel is in many cases largely determined by the roll pass designer.

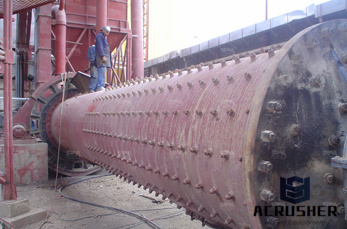

Being a reputed firm in the organization, we are engaged in manufacturing and supplying an assortment of Steel Rolling Mill Machine. This rolling mill is widely used in the steel industry for rolling steel in various applications. Offered rolling mill is manufactured under .

This mill is increasingly used for stainless steel strip rolling, either as inline tandem mill for cold rolling or in the entry section of hotstrip stainless steel annealing and pickling lines to roll black hot strip with highest pass reductions and simultaneous improvement of the strip shape.

We are manufacturer and supplier of high quality heavy duty rolls which are used in tube mills. The high quality range of tube mill roll sets is manufactured in accordance with the requirements of the clients. The tube mill rolls are are manufactured using highgrade material and are efficient, durable and are capable of achieving high tolerance for heavy duty operation in a tube rolling mill. .

talking about the steel rolling mill roll jrtechin talking about the steel rolling mill roll Rolling (metalworking) Wikipedia In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform

Dec 10, 2015· Rolling mill Rolls and Roll Shop Rolls are the main and very costly consumables in a rolling mill. They are used to roll steel in the rolling mill and their performance depend on many factors which include the materials used and the .

rolling mill, dedicated roll cooling systems are required to fulfill the required functions. Examples are suitable roll cooling and lubricationsystems to fully utilize the advantages of HSS rolls in hot strip mills, and selective roll cooling systems as a method to control the flatness of the strip in cold rolling mills.

offers 3,388 small rolling mill products. About 12% of these are steel sheets, 7% are grinding equipment, and 5% are paper product making machinery. A wide variety of small rolling mill options are available to you, There are 3,387 small rolling mill suppliers, mainly located in Asia.

Jul 26, 2007· HOT ROLLING MILL PLANT ... Hot vs Cold Rolled Steel, Whats the difference? Duration: 10:23. ... steel 8mm 24mm rebar rolling mill production line Duration: ...

Nov 21, 2015· Cold rolling of hot rolled steel is important, due to high accuracy and lack of oxide scaling. It is carried out below the recrystallization temperature and introduces work hardening. The starting material for coldrolled steel sheet is pickled hotrolled coil from the continuous hotstrip mill.

Sep 09, 2009· I''ve been toying with the idea of converting a jeweler''s rolling mill for rolling hot steel. My power hammer will forge steel down to .16 so I would be using the rolling mill just for thinning bars. Mostly thinning 3/16 down to 1/8 and occasionally 1/16.

Scratch from cold rolling mill Stainless steel defects Rolling defects Scratch in cold rolled steel strip Rolling defects Scratches Heavy plate defects Rolling defects Scratches, grooves and gouges Hot rolled flat steel products Rolling defects ... Surface wrinkle defect of carbon steel Rolling defects Swealed Hot rolling ...

Rolling Mill INDUSTRY TRAINING Rolling Mill INDUSTRY TRAINING AGENDA* Day 1 n Making bearinggrade steel n Rolling mill configuration and design n Rolling mill related equipment n Bearing fundamentals n Featured products and services n Condition monitoring basics Day 2 n Chock and roll repair overview n Bearing damage analysis n Roll and chock ...

The Hot Rolling Process The primary function of the Hot Strip Mill is to reheat semifinished steel slabs of steel nearly to their melting point, then roll them thinner and longer through 12 successive rolling mill stands driven by motors totaling 77,000 hp, and finally coiling up the lengthened steel sheet for transport to the next process.

Jan 09, 2017· Related to study. SMS group Cold rolling Pickling Line Tandem Cold Mill of JSW Steel Ltd Duration: 8:56. SMS group 38,433 views

steel, plus rolling on modernized hot strip mills. This enables AK Steel to meet the most demanding customer specifications for hot bands, hot rolled sheet coils, cut and milledge coils, plus cut lengths and custom blanks. Pickling helps produce excellent strip surfaces. Appliance Frames Automotive Construction Shelving Truck Frames

After a roll change or a mill stop rolls need some time to return to stable thermal conditions, every new bar entering the mill creates an impact, ... and sometimes there are really severe rolling accidents, due to faults by operators, weak rolled materials with .

Improved finish, higher quality and greater consistency are some of the benefits that our new I2S rolling mill is providing to customers. With the installation of this mill, Greer Steel''s temper capacity grew by 3,000 lbs/month, allowed better utilization of the finish rolls, and provided greater diversity of roll finish.

Rolling Process. The article mentions that the steel is hot rolled, to have a homogenous crystalline structure (which makes sense), but in the sentence right after, it says that the rolling also elongates the crystalline structure, which AFAIK only happens if the metal is cold rolled.

WhatsApp)

WhatsApp)