Nanoceramics from the ball mill ScienceDaily

Nanoceramics from the ball mill Date: October 30, 2019 ... However, material scientists are not that interested in it as a gemstone. Because it can almost compete with diamond in terms of hardness ...

WhatsApp)

WhatsApp)

Nanoceramics from the ball mill Date: October 30, 2019 ... However, material scientists are not that interested in it as a gemstone. Because it can almost compete with diamond in terms of hardness ...

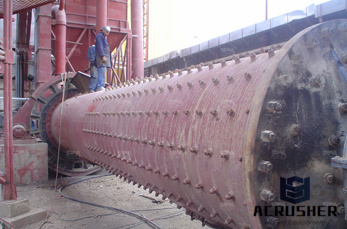

Ball Mills Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800''s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

Milling cutters are cutting tools typically used in milling machines or machining centres to perform milling operations (and occasionally in other machine tools).They remove material by their movement within the machine (, a ball nose mill) or directly from the cutter''s shape (, a .

Explain the role of ball mill in mineral industry and why it is extensively used. Describe different types of ball mill design. ... Pebbles and ceramic media (ρ B = ) are adequate for soft materials. Ball Size Distribution. As the mill starts, grinding action and throughput increases. However, after reaching a critical speed, the mill ...

Quick Test for Percent of Deleterious Material Prepared by Missouri University of Science and Technology and ... (Total Deleterious Material, Total Deleterious Material Plus Hard Chert, Deleterious Rock Plus Soft Chert, and Shale). ... wet ball mill, wet ball mill .

Planetary ball mills 9 . Vibration Mills 10 . Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µm Setting of vibrational frequency: digital, 3 30 Hz (180 1800 min1)

3 days ago· Nanoceramics from the ball mill Nanometersized corundum particles for automotive catalysts and particularly stable ceramics can now be produced amazingly easily ... and materials for dental ...

The ball mill contains a hollow cylindrical shell that rotates about its axis. This cylinder is filled with balls that are made of stainless steel or rubber to the material contained in it. Ball mills are classified as attritor, horizontal, planetary, high energy, or shaker.

Home / Browse Our Products / Material Specific End Mills / End Mills for Hardened Steels: End Mills for Hardened Steels Finishers Ball. Photo is an illustration of an exemplary tool. Carbide End Mills for Hardened Steels Finishers Ball. Designed to profile and finish hardened tool, die, and mold steels 46Rc to 68Rc ; Select carbide ...

BALL MILL METHOD FOR DETERMINING THE DISINTEGRATION OF FLEXIBLE BASE MATERIAL TXDOT DESIGNATION: TEX116E CONSTRUCTION DIVISION 3 – 5 LAST REVIEWED: SEPTEMBER 2014 water for one hour. If 2 L ( gal.) of water do not fully cover the sample, use the smallest amount of water possible to do so. Note 1—Use the dry sieve analysis as a rough check for specification .

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill can grind various ores and other materials either wet or dry.

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications.

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Ball Mills are the most effective laboratory mills for rapid batchwise comminution of mediumhard, soft, brittle, fibrous, temperaturesensitive and moist samples down to the finest particle size. The comminution of the material to be ground takes place through impact and friction between the grinding balls and the inside wall of the grinding ...

The present invention relates to a soft ball cement mill particle size measurement method. Select the auxiliary variables: the separator speed, feed rate and inlet pressure separator, classifier load as measured auxiliary variables soft finished model size. Data Pretreatment: filtering the raw data, filtered and standardized. Based Soft Sensor Modeling (genetic algorithm optimization neural ...

Table of Bond Work Index by Minerals. ... This Table of Ball Mill Bond Work Index of Minerals is a summary as tested on ''around the world sample''. You can find the SG of each mineral samples on the other table. ... Table of materials reported by Fred Bond .

It is commonly used on soft materials, stainless steel and super alloys. Tribon is a proprietary coating exclusive to Seco Tools, Inc. Uncoated (3886) ... Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing. A ball end mill is constructed of a round cutting edge and used in the ...

Materials below their T g are generally friable to some degree. Keeping the mill and material from overheating. Hard to mill materials generate a lot of heat during milling, and materials must stay below their melt temps or softening points to be friable. Temperature control to prevent hazardous decomposition in the high energy environment of ...

Jul 07, 2017· A ball mill grinds material by rotating a cylinder filled with media (typically metallic or ceramic balls) mixed with a continuous flow of feed and recycled material. At slower rotational speeds, the grinding media creates a cascade motion where the media is mainly rolling and shear forces for grinding are generated.

Ougar8 Radius 1 2 3 CNC Milling Cutter Center Cutting Tungsten Carbide TiAlN Coated Ball Nose End mill 2 Flutes Endmills Spiral HRC45 Micrograin solid carbide Router bits(6pcs/Lot)

Nov 24, 2010· In this study, we investigated the ability of airjet and ballmill to achieve adequate micronization on the lab scale using a model soft material, Pluronic® F68. Material mechanical properties were characterized using the nanometer 600.

Jun 19, 2015· The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding. The Motion of the Ball .

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced.

WhatsApp)

WhatsApp)